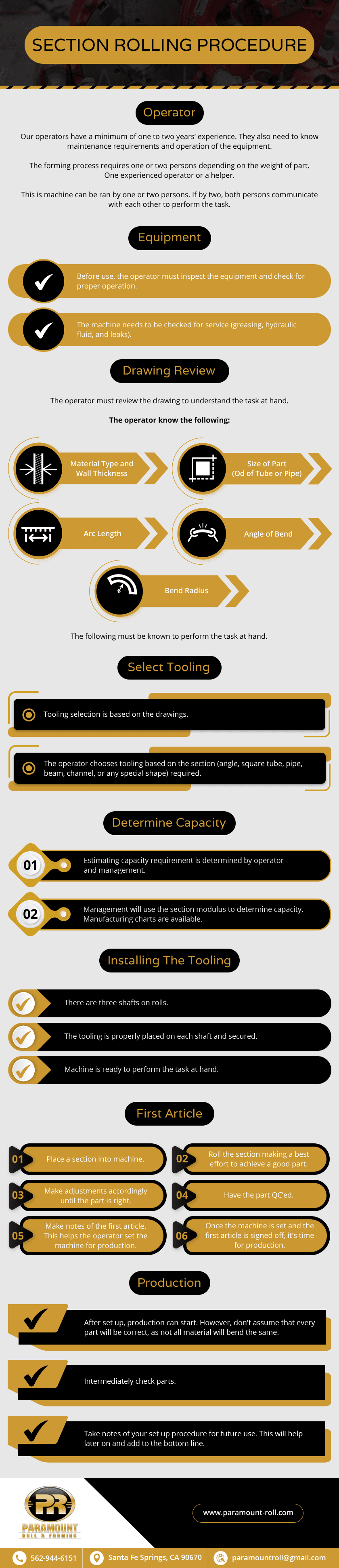

Operator:

Our operators have a minimum of one to two years’ experience. They also need to know maintenance requirements and operation of the equipment.

The forming process requires one or two persons depending on the weight of part. One experienced operator or a helper. This is machine can be ran by one or two persons. If by two, both persons communicate with each other to perform the task.

Equipment:

Before use, the operator must inspect the equipment and check for proper operation. The machine needs to be checked for service (greasing, hydraulic fluid, and leaks).

Drawing review

The operator must review the drawing to understand the task at hand. The operator know the following:

-

Material type and wall thickness

-

Size of part (od of tube or pipe)

-

Arc length

-

Angle of bend

-

Bend radius

The following must be known to perform the task at hand.

Select tooling

Tooling selection is based on the drawings. The operator chooses tooling based on the section (angle, square tube, pipe, beam, channel, or any special shape) required.

Determine Capacity

Estimating capacity requirement is determined by operator and management. Management will use the section modulus to determine capacity. There are manufacturing charts available. This is important for a safe production of the part.

Installing the tooling

There are three shafts on rolls. The tooling is properly placed on each shaft and secured. Machine is ready to perform the task at hand.

First article

Place a section into machine. Roll the section making a best effort to achieve a good part. Make adjustments accordingly until the part is right. Have the part QC’ed. Make notes of the first article. This helps the operator set the machine for production. Once the machine is set and the first article is signed off, then it time for production.

Production

After set up production can start. However don’t assume that every part will be correct. Not all material will bend the same. It is important to intermediately check parts.

Take notes of your set up procedure for future use. This will help later on and add to the bottom line