Need help with metal bending solutions? Look no further than Paramount Roll & Forming, which has become a leader in producing and fabricating induction bending parts and assemblies. With a team of experienced personnel working around the clock, they provide proven quality products without sacrificing speed or cost.

With decades of experience, these specialists have what it takes to take on any job requiring expert-level induction bending services. Whether looking for one part or hundreds, Paramount Roll & Forming is here for all your bending needs!

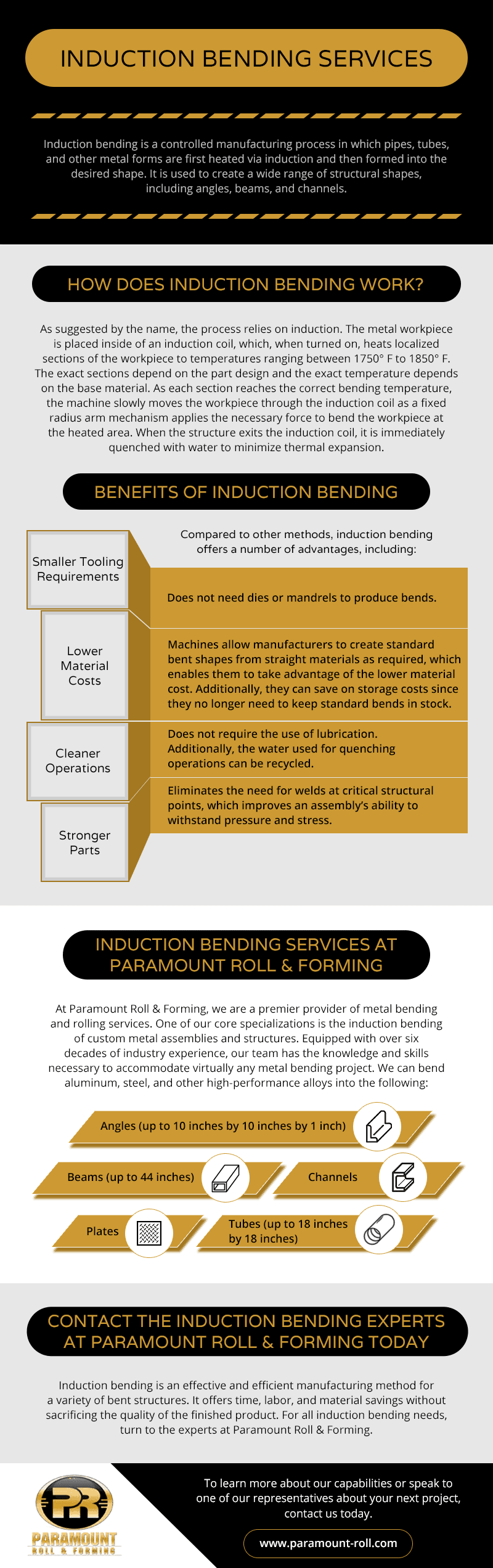

How Does Induction Bending Work?

Induction bending is a highly sophisticated metal bending process that leverages the precision, efficiency, and consistency of heat induction technology.

This technique uses a straight pipe, tube, or other symmetrical section that is carefully positioned on a machine bed, where a swing arm is configured to achieve the desired radius. The process involves the use of a heat induction coil, which creates an alternating magnetic field that induces eddy currents in the metal, generating friction-based heat. This localized heating is exclusively focused on the specific area requiring bending. Simultaneously, a controlled and monitored rate of hydraulic pressure is applied to push the material through the induction coil.

To prevent unwanted deformations, cool air and water are efficiently sprayed onto the sections surrounding the heated zone. The synergies between the precise heating, speed, and cooling enable the material to bend at tighter radii without significant cross-sectional deformations. In essence, induction bending is a state-of-the-art technique that harnesses the power of controlled heat and magnetic fields to transform straight sections into accurately curved components, ensuring top-notch quality and performance in various applications.

Advantages of Using Induction Bending

It has many advantages over traditional manual or hydraulic pipe bending methods, including:

The advantages of induction bending are that this machine can bend much tighter radiuses than the cold bending machine.

- Increased precision: The heat generated by induction pipe bending ensures that each bend is perfectly formed with minimal variation in accuracy between sections. This makes it possible to create intricate designs with exact angles and curves impossible to achieve through other means..

- Versatility: One of the most significant advantages of using heat induction bending is its versatility. It can be used to shape metal pipes and tubes of virtually any size, shape, or thickness. This makes it ideal for various applications, from automotive parts to medical devices.

- Durability: Heat induction bending reinforces the material produced significantly more than traditional procedures such as cold-bending, which can cause cracks and weak areas in the finished product. This makes induction pipe bends much more durable and less likely to fail under pressure or stress.

- Reduced Material Waste: The localized nature of induction bending also helps reduce material waste, as there is less risk of overheating or distorting the entire workpiece.

- Energy Efficiency: Induction bending often consumes less energy than cold bending. This is due to the localized heating process, which minimizes heat loss and reduces the overall energy required to achieve the desired bend. The induction process provides better control over the temperature and heating pattern, which means that energy is used more efficiently to achieve the desired bend without overheating or wasting energy.

Choose Paramount Roll & Forming for High-quality Induction Bending Services

At Paramount Roll & Forming, we have the experience and knowledge to do induction bends better than anyone else. We maintain a strict quality control process that ensures each part is perfectly bent according to customer specifications.

Our experienced engineers use advanced software tools to calculate the optimal angle for each bend and generate detailed reports on the finished parts. We can produce bends with tight tolerances, ensuring each part meets your requirements.

Our production staff is highly trained in bending different materials, like steel and stainless steel.

Our commitment to quality extends beyond the production process. We understand that a quick turnaround time is important to our customers, so we provide fast and reliable delivery. You can trust us to get your parts on time and in perfect condition when needed. Contact us today — let us show you why we are the best choice for your project.