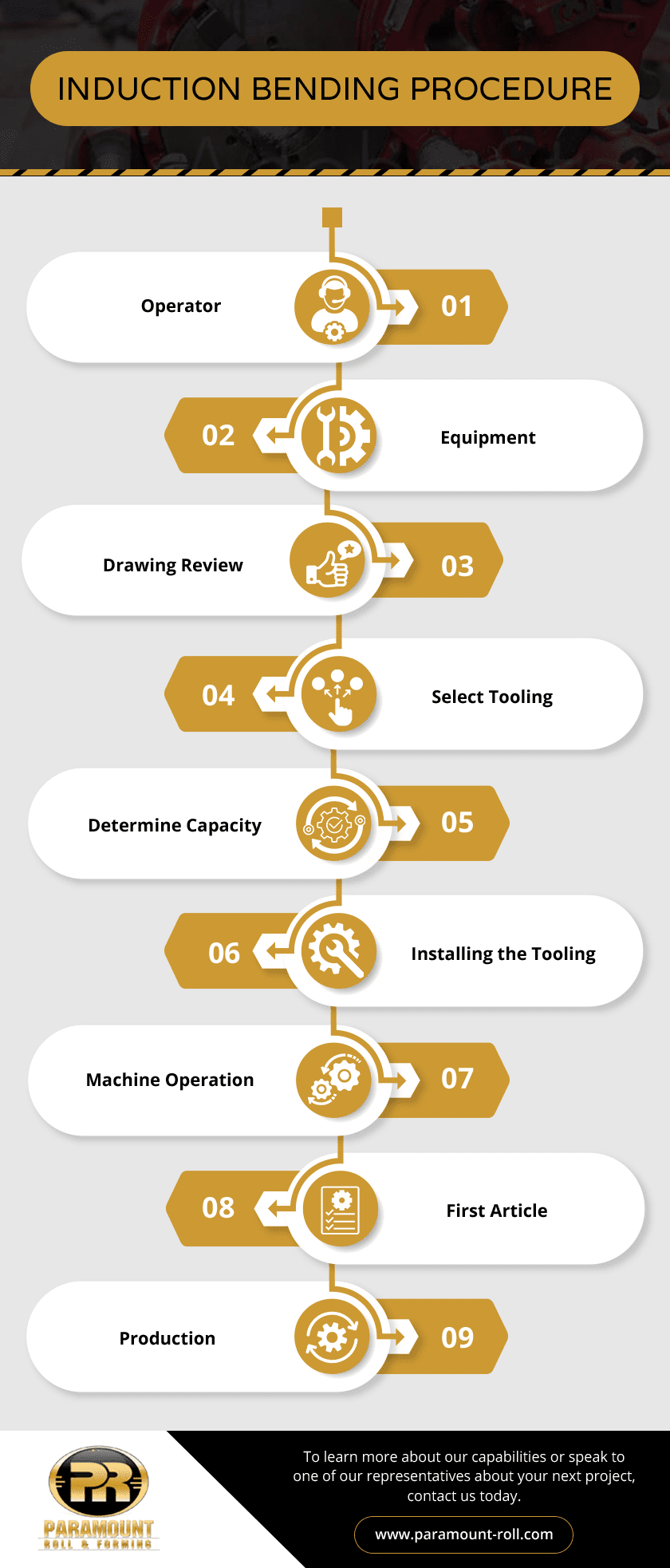

Operator:

Our operators have a minimum of one to two years’ experience. They also need to know maintenance requirements and the operation of the equipment.

The forming process requires one or two persons depending on the weight of the part. One experienced operator or a helper. This is a machine that can be run by one or two persons. If by two, both persons communicate with each other to perform the task.

Equipment:

Before use, the operator must inspect the equipment and check for proper operation. The machine needs to check for service (greasing, hydraulic fluid, and leaks).

Drawing review

The operator must review the drawing to understand the task at hand. The operator knows the following:

- Material type and wall thickness

- Size of part (od of tube or pipe)

- Arc length

- Angle of bend

- Bend radius

The following must be known to perform the task at hand.

Select tooling

Tooling selection is based on the drawings. The operator chooses tooling based on the section (angle, square tube, pipe, beam, channel, or any special shape) required.

Determine Capacity

Estimating capacity requirements is determined by the operator and management. Management will use the section modulus to determine capacity. There are manufacturing charts available. This is important for the safe production of the part.

Installing the tooling

An induction bender requires very little tooling. Most of the tooling is part of the machine therefore conventional. However, there are two tools that are interchangeable. The clamps on the arm. And the reaction rolls. This makes this machine desirable because there is no tooling required to charge for it.

Machine Operation

The material is placed into the machine. A copper coil that matches the section is connected to the induction heater transformer. The radius arm is clamped to the section. The induction heater is then turned on and a high DC current is induced into the coil. The coil is now trying to move the molecules in the material, therefore, creating friction heating it to a specified temperature. Temperature is determined by frequency. Once the desired temperature is achieved a clear heat ban accrues around the section. At this time variable speed hydraulics will conveyor the section through to coil to the desired radius. In some cases, quenching is required.

First article

Once the part is finished the part is QC’ed. If the part does not pass then the part is reworked by cold bending processes and reQC’ed. Then adjustments can be made in the machine to minimize rework

Production

After set up production can start. However, don’t assume that every part will be correct. Not all materials will bend the same. It is important to intermediately check parts.

Take notes of your setup procedure for future use. This will help later on and add to the bottom line

If you have more questions or would like to learn more about how we Induction bend here at Paramount Roll, please contact us