Paramount Roll & Forming offers superior metal fabrication services, specializing in various metal bending and rolling methods. We have been a trusted manufacturer for many years, allowing us to gain extensive background knowledge in the varying industries we serve. We’re confident that we can work on your project due to our expertise in diverse areas. Therefore, you can trust us to deliver outcomes that will improve your bottom line.

Our in-house facility is equipped with innovative technology, ensuring your projects are completed precisely and consistently. We can guarantee that our metal bending and rolling services accomplish the outcomes you’ve been looking for.

Metal Bending by Paramount & Roll Forming

Metal bending is a process where sheet metal is deformed to achieve a predetermined form through different bending techniques. Force is applied to bend the sheet at an angle until it reaches an anticipated shape, usually “V” or “U.” The main tool used for this process is called a press brake, consisting of a punch and die.

Our metalworking experts understand our client’s challenges, and we’re ready to provide solutions that are second to none through our metal bending services. This type of fabrication is the backbone of innumerable industries, so we’re highly equipped to handle your projects, such as fabricating structural steel products.

The Basic Types of Metal Bending

There are numerous types of metal bending techniques, and the correct procedure depends on the material and thickness of sheet metal that needs to be bent. Our team will also analyze your project prerequisites and determine the best method to reach excellent outcomes.

The basic types of metal bending include:

- V-bending: The most common and basic bending method is called V-bending, which employs a V-shaped die and punch. These tools force the metal workpiece into the die’s V-shaped groove or crevice, and the punch forces the substrate to bend at different angles.

- Air bending: Another common metal bending method is air bending, which uses the same V-shaped die and punch as V-bending. However, the punch doesn’t force the workpiece into the cavity’s bottom. Instead, a space or “air” is left underneath the sheet. This space allows for more bend angle control.

- Bottom bending: Also called bottoming, it has similarities with air bending. However, the difference is their radius. Also, the die and punch don’t make contact with the workpiece, and there’s not enough tonnage to make an imprint. Some advantages include lesser spring backs, making it safer than other bending procedures.

- Coining: During this process, more tonnage is used while the punch presses the workpiece into the die. The force is five to 30 times stronger than the one used in air bending, causing permanent deformation. Although it has higher precision, it’s more expensive. Therefore, not all projects prefer using this option.

Other types of metal bending are Rotary, Joggling, Wiping, Folding, and Rolling. We depend on your specifications and requirements before choosing the best technique to ensure the result exceeds your expectations.

Common Applications of Metal Bending

Multiple demanding industries rely on metal bending to support their operations. Some examples are Aerospace, Automotive, Construction, Art, Architectural, Residential, Commercial, and more.

Products made through this manufacturing process are used in a broad range of applications, some of which include:

- Tubes

- Pipes

- Railings

- Spiral staircases

- Structural components

- Outdoor metalworks

We focus on fabricating large metal assemblies and parts, leveraging precision equipment and advanced technology to accomplish the highest accuracy and repeatability standards.

What is Metal Rolling?

Roll-formed steel is produced through our metal rolling process. Mainly used to fabricate large parts found in the construction sector, this metal bending technique is utilized to form cones and tubes in different sizes, shapes, and radius bends.

Metal rolling also comes in different types, including:

- Controlled rolling

- Roll forming

- Roll bending

- Profile rolling

- Ring rolling

Most rolling machines employ two rollers where the workpiece is fed through two rollers. Afterward, the workpiece will come out on the other side with a curve. The operator will reverse the rollers and run the sheet metal back on the opposite side to enhance its curves until the desired angle or bend is reached.

Wide Range of Applications Found in Metal Rolling

Like metal bending, metal rolling is also required in numerous sectors. A few of its typical applications include:

- Wheel rims

- Tubes and pipes

- Rods

- Slabs

- Steel blooms

- Busbars

- Heavy cross-sections

- Beams

These structural steel products are also available in aluminum and high-performance alloys for sturdier and more durable results that last. Our roll-forming services also achieve complex bending geometries for unique projects.

Quality Custom Metal Bending and Rolling Services

We work closely with our clients in every step of the process, from design to delivery. We understand that each industry has different demands, so our experts are trained to handle the challenges our clients face with their projects.

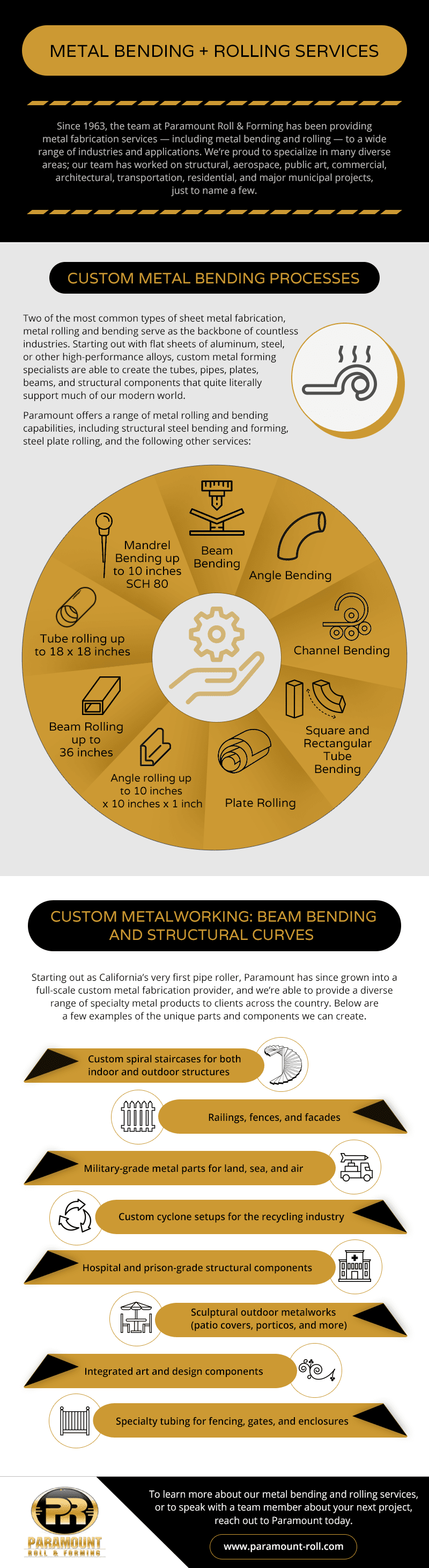

Apart from metal bending and rolling, other fabrication services we offer include:

- Beam bending and rolling: We can successfully manipulate the beam’s shape and form using various bending and rolling methods.

- Angle iron bending and rolling: Angle iron is produced through bending and rolling using angle rollers and benders by shaping them into a particular form.

- Channel bending: Shaped punches and dies are used to form a sheet metal channel.

- Square and rectangular tube bending: Bending square and rectangular tubes involves the elongation of the bend’s outer diameter and internal diameter’s compression.

- Plate rolling: Cylindrical items are achieved through plate rolling.

- Tube rolling: This method involves rolling sheet metals into tubes or other tubular items.

- Mandrel bending: A type of rotary bending method where a piece of rod is inserted inside a tube or pipe during the bending process.

These services can handle tight tolerances without affecting the integrity of the product. As leaders in metal fabrication, we can provide a diverse range of specialty metal products for unique applications.

Choose Us to Fulfill Your Metal Bending and Rolling Needs

We started as the first pipe bender and roller in California, expanding our operations into a full-scale custom metal fabrication provider. If you’re looking for experts who can work with you and guarantee the results you’re looking for, we’re here to guide you throughout the process.

If you’re interested in our service and want to know more about our capabilities, don’t hesitate to contact us today. You can also request a quote, and our team will find a cost-effective solution tailored to your needs.